How to Convert USB Type-A Devices to USB Type-C: A Step-by-Step Guide

Introduction

USB (Universal Serial Bus) has been the cornerstone of connectivity for over 20 years. It has undergone various updates and changes, evolving into a complicated system of connectors and sub-connectors. The latest standard, USB Type-C, promises a universal solution with its reversible design, enhanced power delivery, and ability to replace all previous sub-connectors.

However, as we transition to this new standard, many older devices still rely on USB Type-A, leaving us stuck with dongles and adapters to make them compatible with Type-C ports. If you’re tired of this transitional hassle, this guide will teach you how to convert USB Type-A devices into USB Type-C.

Disclaimer: This guide is intended for educational purposes only. Any modifications you make to your devices are at your own risk. We are not responsible for any damages, including bricking or malfunctioning devices.

Understanding USB Evolution

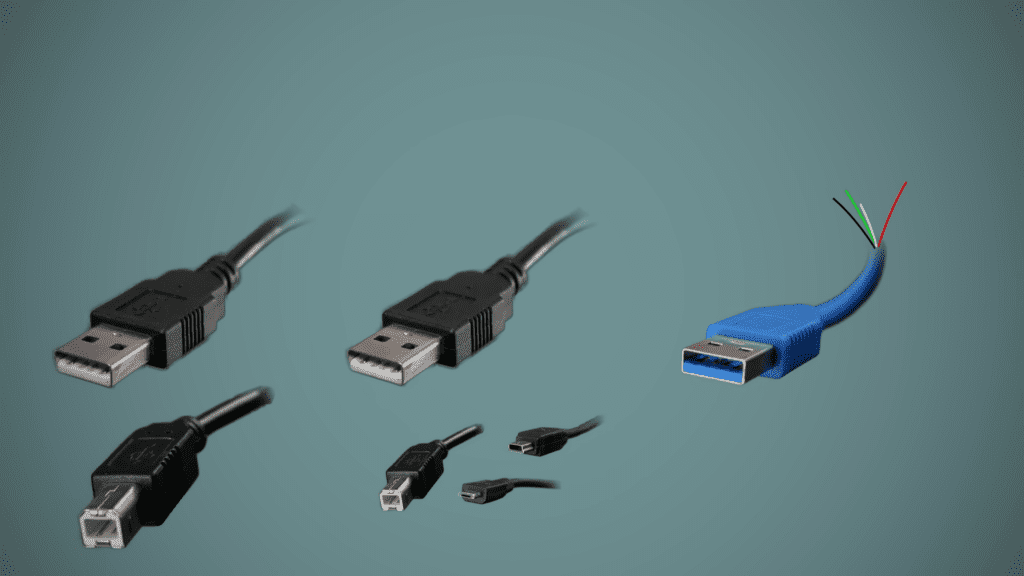

Before diving into the conversion process, let’s take a brief look at USB’s evolution:

- USB 1.0 and 2.0: Introduced the standard USB Type-A and Type-B connectors. USB 2.0 improved data transfer speeds while retaining the same wiring structure.

- USB 3.0: Added more data transfer wire pairs to significantly increase speed while maintaining backward compatibility with older connectors.

- USB Type-C: A smaller, reversible connector designed to simplify connectivity. It supports faster data transfer, higher power delivery, and compatibility across devices, whether they act as hosts or peripherals.

What You’ll Need

To convert your USB Type-A device to Type-C, gather the following:

- USB-C breakout board

- Soldering iron and solder

- Old USB cable (for wires)

- Wire cutters

- Multimeter (optional but recommended)

- Sugru or similar moldable glue (for protection and aesthetics)

- 4.7kΩ or 5.1kΩ resistor

Step-by-Step Guide

Step 1: Open the Device

- Open the USB plug of your device to access the PCB (Printed Circuit Board).

- Identify the copper traces inside the USB Type-A connector. Typically:

- Outer traces: Power (VCC and GND)

- Inner traces: Data (D+ and D-)

Step 2: Prepare the USB-C Breakout Board

- Obtain a USB-C breakout board. This small PCB has solder pads labeled for Type-C pins.

- Locate the solder pads:

- A6 and A7: Data pins for USB 2.0 connectivity.

- G4 and V4: Ground and Voltage pins.

Step 3: Solder the Wires

- Cut open an old USB cable to extract its wires (red for VCC, black for GND, green for D+, and white for D-).

- Add a dab of solder to the breakout board’s pads (A6, A7, G4, V4).

- Solder the wires as follows:

- A6 (D+): Green wire

- A7 (D-): White wire

- G4 (Ground): Black wire

- V4 (Voltage): Red wire

Step 4: Connect to the Device

- Solder the wires to the corresponding copper traces on the device’s PCB. Use the same VCC, GND, D+, and D- configuration.

Step 5: Configure the Breakout Board for Sub-Device Mode

- USB Type-C requires the device to signal whether it acts as a host or sub-device.

- Check if your breakout board has resistors pulling up voltage on pins A5 and B5. If so, scrape away the trace connected to these resistors.

- Replace it with a 4.7kΩ or 5.1kΩ resistor connected to ground (GND). This ensures the device operates as a sub-device.

Step 6: Test the Connection

- Double-check all soldered connections.

- Plug the modified device into a USB Type-C port.

- Verify functionality. If it doesn’t work, recheck your wiring and resistor configuration.

Protecting Your Modification

Exposed PCBs and wires can be fragile and unsafe. To protect your modification:

- Use Sugru or moldable glue to create a custom case around the breakout board and wires.

- Ensure no wires are shorted and all connections are secure.

- Let the glue set to form a durable, shock-resistant shell.

Application Examples

This method isn’t limited to simple devices like USB receivers. You can adapt it to other devices such as:

- Thermal cameras with micro-USB connectors

- External hard drives

- Older smartphones or accessories

Important Notes

- Always use a multimeter to check voltage and pin configuration before soldering.

- Proceed with caution. Incorrect wiring can damage your device or the connected port.

- This process is best suited for hobbyists with basic soldering experience.

Conclusion

Converting USB Type-A devices to USB Type-C is an effective way to bring older devices into the modern era. While it requires some technical skills and patience, the result is a more streamlined and adaptable device.

Remember, this guide is for learning purposes, and any modifications are done at your own risk. If you’re not confident in your skills, consider seeking help from someone experienced in soldering and electronics.

Tags

USB conversion, USB Type-C, USB Type-A to Type-C, DIY USB mod, USB breakout board, soldering guide, USB-C devices, electronics modification

Hashtags

#USBConversion #USBTypeC #ElectronicsMod #DIYUSB #TechTutorial #USBDevices #LearnSoldering